1. Too much volume - Too much bread volume can be possibly caused by :

Solution :

- Check yeast quantity

- Check recipe

- Final proof too high

- Check scaling weight

2. Badly shaped :- The bread may be shaped bad due to :

- Moulder setting too loose

- Dough placed wrongly in tin

- Poor hand moulding

- Tight dough

- No intermediate proof

Solution :

- Check dough placement in time

- Increase water quality

- Rest dough for 10 minutes after scaling.

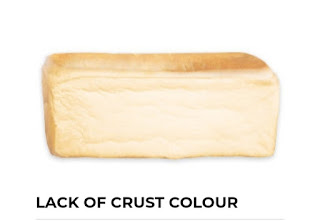

3. Lack of crust colour :- The lack of crust colour may be due to:

- Baking temperature too low

- Baking temperature too short

- Too little concentrate

- Inconsistent oven heat distribution

Solution :

- Increase baking temperature

- Extend baking time

- Check recipes and scale properly

4. Cracked Top crust :- cracked Top crust possibly can be caused by :

Solution :

- Check proofer setting

- Extend baking time

- Place trolley in proofer after moulding

5. Holes in Bread :- Holes in bread can be possibly caused by :

- Too much dusting flour on table

- No intermediate proof

- Too much flour in final moulder

- Proofer too hot

- Poor hand moulding technique

Solution :

- Reduce dusting floor

- Rest dough for 10 minutes after scaling

- Ensure proper moulding

- Reduce proofer temperature to 40 degree Celsius

6. Poor Retarding :- Poor retarding can be caused by :

- Dough dried out in fridge

- Dough temperature too high

- Fridge temperature too high

- Dough left in fridge for too long

Solution :

- Reduce dough temperature

- Reduce refrigerator temperature

- Ensure fridge temperature between 3 - 5 degree Celsius.

7. Collapsed bread :- The bread may possibly collapsed because :

Solution :

- Reduce water quantity

- Increase mixing time

- Check yeast quantity

- Ensure correct final proof

8. Bread stick in tin :-

Possible cause:

Solution:

- Extend Baking time

- Reduce water quantity

- Change tin oil and check proofer steam setting

9. Poor shelf life :- The poor shelf life can be caused by :

Solution :

- Increase water content

- Reduce Baking time

- Ensure package at correct temperature

- Cool bread in controlled area.

10. Thick crust :- The thick crust is caused by oven too cold and Dough too stiff. It can be prevented by increasing Baking temperature and water quantity in dough

11. Holes at bottom :- Holes at bottom can be caused if Bad moulding used and damaged bread tin bases uses which can be controlled by ensuring even moulding and replacing bread tins

12. Holes under Top crust :- The Hole under Top crust will be caused if the oven have too much deck heat on top,moulding too loose and too much flour on table. It can be controlled by reducing oven heat on top ,reducing dusting flour and by reducing mixing time.

13. Side collapsing :- The slides of bread may collapse if bread is left for too long in tins, if too much yeast is added and under baked. It can be eliminated by extending baking time and , using correct yeast and removing from tin immediately after baking.

0 Comments

If you have any doubts , please let me know