Baking is the process of cooking food without direct exposure to flame. It involves dry heat. Typically, Baking is done in oven and one of the oldest cooking methods. Baking is done for fabrication of Bakery products like cookies , Bread , Pastries , pies. The word Bake comes from the word bhôg if looked at Indo - European language which meant to dry in oven. Baking involves cooking in dry heat in oven.

INGREDIENTS USED IN BREAD MAKING

The main ingredients used in bread making are yeast , Flour , Salt , Eggs , Fat , water or milk.

1. Flour : Flour form the main ingredient in bread making . We need floor with high gluten content while making breads so strong flour is recommended.

2. Yeast : yeast is a raising Agents we used while bread making . The yeast converts sugar into carbon dioxide. The trapped Carbon dioxide expand during baking process thus, aerating product. Yeast gets killed in 70 degree Celsius and works best between 25 - 40 degree Celsius.

3. Salt : salt is essential component for bread making. It control activity of yeast and imparts flavour. We should always mix salt with flour at beginning itself. The salt will also affect crust colour and crumb by controlling on rate of fermentation.

Note - if we use less salt we will get less crust colour and large volume and if we add more salt it will give more crust colour, slow activity of yeast.

4. Sugar : Apart from developing flavour and colour sugar also act as food for yeast. We have to keep in mind that lower the sugar lesser will be the crust colour and not enough volume. Our yeast works best on 10% sugar solution in dough. It also helps bread in retaining Moisture.

5. Milk : Lactose a type of sugar found in Milk cannot be fermented by yeast so it remains in dough till end thus helping bread making softer , whiter , moisture and increase nutritional value.

6. Egg : It helps to make bread softer and gives lightness and colour to the bread.

7. Fat : we used fat like oil / Butter in bread fabrication whose main role is to provide flavour and softness to texture along with nutritional flavour.

8. Bread Improver : The Quality of flour differs each time so we will add Bread improver.

PRINCIPLES OF BREAD MAKING

1. SCALING :- This is our first step in bread making . After collecting our ingredients now we will scale them to ensure there is accurate measurement. We have to ensure using as required by the recipe and neither too more nor too less. If we are looking to prepare best quality bread then we have to ensure that all ingredients are fresh .

2. MIXING AND KNEADING :- This is our second step where we mixed all the ingredients. We will first mix dry ingredients and then wet. We are mixing the ingredients to ensure all our ingredients are combined and distributed throughout dough . We will be kneading either by Hand or Dough Mixer. The ingredients are now combined uniformly. We are mixing dough either by straight dough method or sponge Method. The most used method is straight dough method which is very easy , combining the ingredients and and kneading.

3. FERMENTATION : Fermentation is the process where our yeast converts sugar into carbon dioxide. Yeast is used as raising Agents. The carbon dioxide bubble get trapped in dough and when baking the carbon dioxide will rise causing Product to expand. It is very important step in bread making .

4. KNOCK BACK : After Fermentation , now we will fold down dough to remove gas bubble formed by yeast. This step is also called punching down Dough. Punching will also redistribute yeast cell , sugar and moisture so they can be ready again for ferment and rise during proofing stage.

5. PORTIONING , ROUNDING AND SHAPING :

After punching , now we will portion dough. It is portioned to make required desired weight because we want uniformity and even size. Well, after portioning now we will make it smooth round and finally shaped to require form.

6. PROOFING : In proofing , we will ferment dough under controlled Temperature so that our dough become doubles in size. It is done in proofing chamber where the dough is Fermented under controlled Temperature. In proofing cabinet the the temperature of 25 degree Celsius and 90 % humidity is Maintain. It is also known by proving and is a step where dough is allowed to rest final time before baking.

7. BAKING : It is dry heat Medium of cooking in oven. During baking the yeast dies. We will baked at proper temperature with pre heating oven and ensure our product will not overbake.

8. COOLING : After baking the product will will be cooled at room temperature and stored at room temperature. Cooling decreases internal temperature of bakedbread and cooled by placing in cooler racks.

EQUIPMENTS USED IN BREAD MAKING

We need variety of equipments for Bread Making. Some of them are :-

1. Scaling machine

2. Sieve

3. Baking trays

4. Bread Moulds

5. Dough mixer

6. Bench Brush

7. Proving cabinet

8. Oven

9. Wooden Table

10. Dough scorer

11. Spray bottle

Faults in Bread Making :-

There are number of factors which are responsible for creating faults in bread which are listed below:

1. Too much volume - Too much bread volume can be possibly caused by :

Solution :

- Check yeast quantity

- Check recipe

- Final proof too high

- Check scaling weight

2. Badly shaped :- The bread may be shaped bad due to :

- Moulder setting too loose

- Dough placed wrongly in tin

- Poor hand moulding

- Tight dough

- No intermediate proof

Solution :

- Check dough placement in time

- Increase water quality

- Rest dough for 10 minutes after scaling.

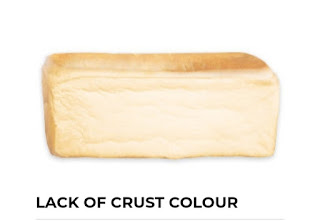

3. Lack of crust colour :- The lack of crust colour may be due to:

- Baking temperature too low

- Baking temperature too short

- Too little concentrate

- Inconsistent oven heat distribution

Solution :

- Increase baking temperature

- Extend baking time

- Check recipes and scale properly

4. Cracked Top crust :- cracked Top crust possibly can be caused by :

Solution :

- Check proofer setting

- Extend baking time

- Place trolley in proofer after moulding

5. Holes in Bread :- Holes in bread can be possibly caused by :

- Too much dusting flour on table

- No intermediate proof

- Too much flour in final moulder

- Proofer too hot

- Poor hand moulding technique

Solution :

- Reduce dusting floor

- Rest dough for 10 minutes after scaling

- Ensure proper moulding

- Reduce proofer temperature to 40 degree Celsius

6. Poor Retarding :- Poor retarding can be caused by :

- Dough dried out in fridge

- Dough temperature too high

- Fridge temperature too high

- Dough left in fridge for too long

Solution :

- Reduce dough temperature

- Reduce refrigerator temperature

- Ensure fridge temperature between 3 - 5 degree Celsius.

7. Collapsed bread :- The bread may possibly collapsed because :

Solution :

- Reduce water quantity

- Increase mixing time

- Check yeast quantity

- Ensure correct final proof

8. Bread stick in tin :-

Possible cause:

Solution:

- Extend Baking time

- Reduce water quantity

- Change tin oil and check proofer steam setting

9. Poor shelf life :- The poor shelf life can be caused by :

Solution :

- Increase water content

- Reduce Baking time

- Ensure package at correct temperature

- Cool bread in controlled area.

10. Thick crust :- The thick crust is caused by oven too cold and Dough too stiff. It can be prevented by increasing Baking temperature and water quantity in dough

11. Holes at bottom :- Holes at bottom can be caused if Bad moulding used and damaged bread tin bases uses which can be controlled by ensuring even moulding and replacing bread tins

12. Holes under Top crust :- The Hole under Top crust will be caused if the oven have too much deck heat on top,moulding too loose and too much flour on table. It can be controlled by reducing oven heat on top ,reducing dusting flour and by reducing mixing time.

13. Side collapsing :- The slides of bread may collapse if bread is left for too long in tins, if too much yeast is added and under baked. It can be eliminated by extending baking time and , using correct yeast and removing from tin immediately after baking.

0 Comments

If you have any doubts , please let me know